News

The importance of impartiality

For Eurovent Certification, impartiality isn’t just a buzz word, but a guiding philosophy. Impartiality is the very cornerstone of Eurovent Certified Performance and the certification process. Most importantly, impartiality is what provides the truth of product performance, creating trust between all players in the heating, ventilation, air conditioning and refrigeration (HVACR) industry. Our latest article explores the importance of impartiality and third-party evaluation, as well as the lengths Eurovent Certification takes to create a truly impartial certification process.

What is third-party certification?

As a third-party certification body, Eurovent Certification works independently of manufacturers (first-party) and their customers (second-party), with no bias towards or against any other party. The value in third-party certification is that product performance is verified by an independent body without a vested interest, with no preconceptions or prejudice. For Eurovent Certification this means guaranteeing that all products will be evaluated transparently and fairly, creating a level playing field for manufacturers large and small.

Impartial and fair certification process

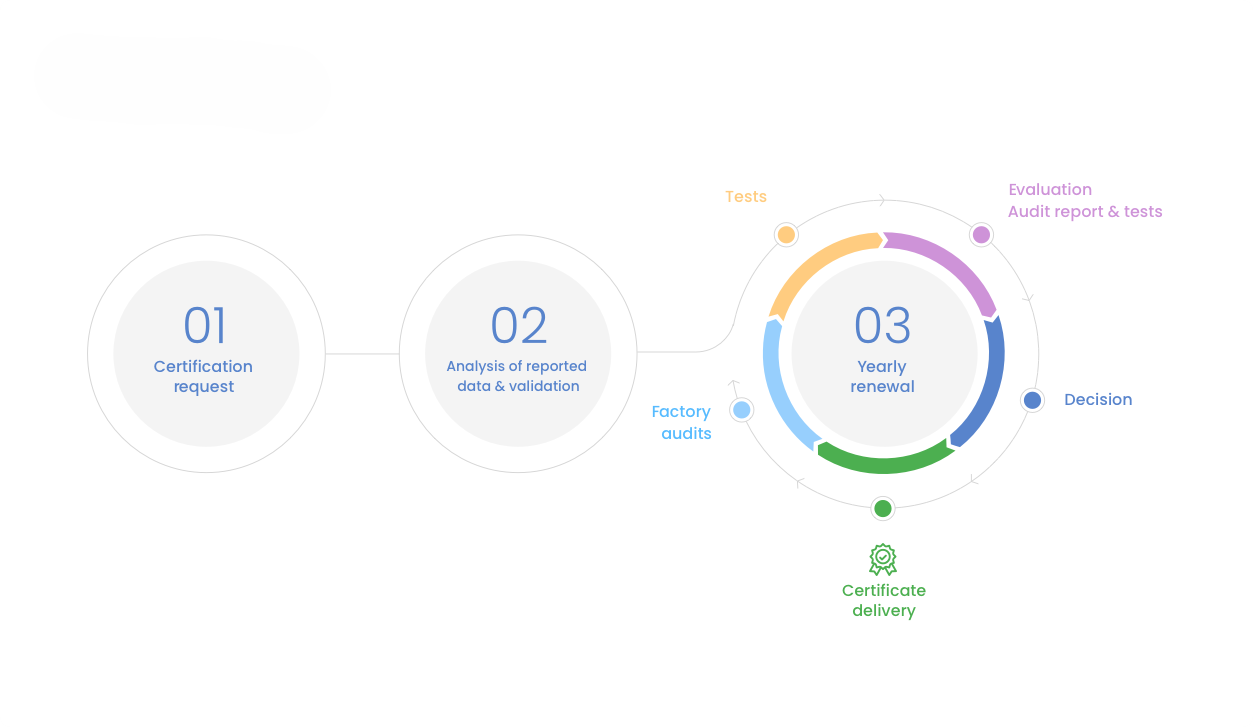

Before we explore how Eurovent Certification upholds its impartiality, first we need to look at the certification process itself. At the very centre of this lies a fair, reliable, and repeatable process, which is applied in exactly the same way to all products and manufacturers within a programme. Eurovent Certification is obliged by its ISO IEC 17065 accreditation (by COFRAC) to provide certification programmes that are non-discriminatory, bound by strict rules on confidentiality and completely impartial.

To ensure evaluation protocols are uniform within a programme, Eurovent Certification:

- Evaluates all products according to the same criteria

- Expresses results in the same unit of measurement – allowing direct comparison across a common language

- Ensures all products within the programme go through exactly the same certification, auditing and surveillance process

- Ensures products with components manufactured across multiple sites (sometimes in different countries), all reach Eurovent Certification standards.

Products tested and evaluated by Eurovent Certification must pass a number of checkpoints to receive certification. State of the art evaluation protocols are used in Eurovent Certified Performance programmes, including:

- Independent laboratory tests

- Manufacturing audits

- Selection software checks

- Product sampling issued from factory

- Product purchase on the market (when possible)

- Data consistency algorithms crossed by product family

Plus:

- Products are tested under conditions coming from European or International standards

- And most products undergo yearly surveillance monitoring to ensure standards remain high.

Keeping evaluation protocols uniform across all countries makes sure the certification process is fair for manufacturers, and certified data is reliable for all users. It also means that product performance can be directly compared with other certified and non-certified models. Certification gives industry professionals and end users access to verified and trusted data wherever in the world they live.

Impartial laboratory testing

To be impartial, all bias needs to be removed, as does any opportunity for those both inside and outside of the process to influence any results. During the laboratory testing aspect of the certification process, Eurovent Certification ensures:

- Laboratories are independent and ISO 17 025 accredited

- There is no direct communication between the testing laboratory and the manufacturer

- Laboratories and their staff have no prior affiliation, or a conflict of interest, with the manufacturer or product they are testing

- Laboratories and all those involved in the testing and evaluation of products must abide by strict confidentiality rules. Test results will only be discussed with Eurovent Certification and no other party (including the manufacturer’s competitors)

- Only test reports ordered directly by Eurovent Certification via independent and accredited laboratories can be considered. Test reports provided by manufacturers are not accepted. *

These extra layers of impartiality also heighten Eurovent Certification programmes above third-party laboratory testing alone, as crucially the laboratory and manufacturer have no direct contact. Additionally, laboratory tests are only part of the process included in programmes such as Eurovent Certified Performance, which add in further checkpoints to reliably validate product energy efficiency and performance.

* Programmes run in partnership with, or using evaluation protocols from a fellow certifier (e.g. Heat Pump KEYMARK, Eurovent Certified Performance for Fans) are exempted from this rule.

Impartial evaluation, auditing, and surveillance

In Eurovent Certified Performance programmes, the results from the laboratory are evaluated alongside information gathered from factory audits and software checks. This is all cross referenced with information provided by the manufacturer. Successfully certified products then join a surveillance process to ensure continued quality. Participants in a number of programmes undergo yearly selection software audits and manufacturing audits, to ensure products continue to comply with certification criteria. This also streamlines the application process when products meet the end of their certification period and need to reapply. Eurovent Certification also undertakes monitoring of communication media of participants, applicants, and non-licensee manufacturers to prevent misuse.

Those undertaking factory audits, software checks and reviewing manufacturer data:

- Are bound by strict confidentiality and impartiality rules

- Must not provide advice or internal audits for manufacturers

- Must have no conflicts of interest when it comes to either the manufacturer or the product

- Must be suitably skilled and competent to undertake the assigned tasks

- Plus, audits are subject to ISO 17 021.

While there are different actors binding together all the strands of the certification and surveillance process, communication is simplified, with all information passed through Eurovent Certification’s client managers, who are the main point of contact for manufacturers.

Proving impartiality with ISO/IEC 17065:2012

Eurovent Certification is accredited as a certification body compliant with ISO/IEC 17065:2012 standard by COFRAC (Accreditation N°5-0517, scope available on www.cofrac.fr). To gain accreditation, COFRAC audits every aspect of Eurovent Certification as an organisation, from documentation and record keeping, to certification processes and complaints procedure. The accreditation also assures that Eurovent Certification staff possess the correct skills and qualifications to competently fulfil their roles, and most importantly, abide to the highest levels of impartiality and confidentiality.

The ISO/IEC 17065:2012 standard by COFRAC demands that all aspects of the organisation and certification process are risk assessed for areas where impartiality and confidentiality could be compromised, with any potential risk swiftly addressed. COFRAC’s auditors evaluate Eurovent Certification every 15 months across a five-year accreditation period to ensure there is no lapse in process or accountability. Just as Eurovent Certification expects manufacturers to uphold exacting standards for their certified products, it is itself under a comprehensive accreditation and surveillance process.

Additionally, Eurovent Certification has a mechanism of safeguarding impartiality, the CPPC, which is an independent body with a balanced composition of manufacturers, consumers and scientists. This committee is regularly consulted on impartiality issues and has the power to take action with COFRAC if necessary.

Types of COFRAC accreditation

It’s important to note that not all certification bodies choose to be accredited or accredited to the same extent. COFRAC offers several types of product certification schemes. All product certification types allow accredited certifiers to:

I) Select products to certify, including planning and preparation activities, specification of requirements, e.g. normative documents, and sampling, as applicable

II) Determine characteristics, as applicable, by testing, inspection, design appraisal assessment of services or processes, other determination activities, e.g. verification

III) Review products by examining the evidence of conformity obtained during the determination stage to establish whether the specified requirements have been met

IV) Decide on certification. Granting, maintaining, extending, reducing, suspending, withdrawing certification.

Eurovent Certification is accredited under scheme type 5. This gives the below additional conformity assessment functions and activities (highlighted in green):

| ISO 17067 correspondence table | ||||||||

| Conformity assessment functions and activities within product certification schemes | Types of product certification schemes | |||||||

| 1a! | 1b | 2 | 3 | 4 | 5 | 6 | Nc | |

| V Attestation, licensing | ||||||||

| a) issuing a certificate of conformity or other statement of conformity (attestation) | X | X | X | X | X | X | X | X |

| b) granting the right to use certificates or other statements of conformity | X | X | X | X | X | X | X | |

| c) issuing a certificate of conformity for a batch of products | X | |||||||

| d) granting the right to use marks of conformity (licensing) is based on surveillance (VI) or certification of a batch. | X | X | X | X | X | X | ||

| VI Surveillance, as applicable by: | ||||||||

| a) testing or inspection of samples from the open market | X | X | X | |||||

| b) testing or inspection of samples from the factory | X | X | X | |||||

| c) assessment of the production, the delivery of the service or the operation of the process | X | X | X | X | ||||

| d) management system audits combined with random tests or inspections | X | X | ||||||

Scheme type 5 is the most comprehensive accreditation applicable for product certification. While all product certification schemes include at least the activities I, II, III, IV and Va, the added value in scheme type 5 is that it fully validates Eurovent Certification’s surveillance process also.

Impartiality guaranteed

With a number of different third-party certification marks and laboratory testing programmes available, manufacturers are advised to do their homework when choosing their certifier. After all, the decisions made impact on their clients, who rely on impartial, reliable, and independent product data when making purchasing, design, installation, and maintenance decisions.

For Eurovent Certification, all the above elements combine to keep certification process fair and impartial, for manufacturers both joining programmes and those established and within the surveillance phase. As a body certified by COFRAC, Eurovent Certification is held accountable, and its impartiality guaranteed.

With 30 years of experience in product performance certification and 40+ different certification programmes, it’s the qualities of impartiality, expertise, fairness and reliability that has made Eurovent Certification the undisputed certification body in Europe for HVACR. With 74% of the European market Eurovent certified, and the only certifier to award the Eurovent Certified Performance mark, its certification programmes have consistently gone above and beyond to find the truth of a product and create trust in the industry.

Find out what Eurovent Certification can do for you: