Case study: The impact of underperformance

- Be non-compliant with regulations

- Use more energy

- Create a larger carbon footprint

- Incur high running costs

- Not meet end user requirements

- Be more prone to faults and breakdown

- Impact on other parts of the system

- Result in penalties, litigation and reputational damage.

Crucially, even a slight underperformance can have a big impact over the lifecycle of the product. The following case study by certified manufacturer, BAC, explains the impact of an underperforming cooling tower on the whole HVAC system.

The project

A new cooling tower is required for use in an industrial HVAC application, operating year-round, with a load variation from 100% in summer to 80% in winter. The cooling tower for this application would be selected for a summer condition to cool 52 l/s of water from 32°C to 27°C at an entering wet bulb temperature of 21°C. The cooling capacity to be rejected would be 1,090 kW.

The cooling towers

The decision maker has the choice between two cooling towers. Model A, is a certified cooling tower, with performance data independently verified. Model B is uncertified. Its data has not been verified and unbeknown to the specifier, its actual performance is 80% of the required duty if using the specified conditions. Therefore, Model B has supply water 1.2°C warmer than designed and the installation will be penalized the entire year by the higher supply water temperature. It will for example, take a wet bulb of 19.3°C to supply the required 32°C / 27°C water temperatures.

| Model A (certified) | Model B (uncertified) | |

| Cooling Capacity (Declared) | 1,090kW (310TR) | 1,090kW (310TR) |

| Summer water condition | 52 l/s (824gpm) @32°C (89.6°F) to 27°C (80.6°F) | 52 l/s (824gpm) @32°C (89.6°F) to 27°C (80.6°F) |

| Entering Wet Bulb | 21°C (69.8 °F) | 19.3°C (66.7 °F) |

| Size | 3.6m (11ft-10’) (L) 2.4m (7ft-10’) (W) 3.5m (11ft-6’) (H) |

3.6m (11ft-10’) (L) 2.4m (7ft-10’) (W) 3.5m (11ft-6’) (H) |

| Fan installed | 15kW (20hp), Absorbed Power = 14.2kW | 11kW (15hp), Absorbed Power = 10kW |

| Sound Power | 99 dBA | 96 dBA |

| Variable frequency drive with concentration factor | 2.5 | 2.5 |

Model B is available at a slightly lower price (approximately 10-15% cheaper). Note that the customer cannot tell that Model B will underperform based on the dimensional data and face values for fan power and sound.

Performance at design conditions

Model A will perform to the specified design conditions as expected. Model B will have to operate slightly outside the design conditions to reach the 1,090kW cooling capacity. The impact of Model B’s underperformance will affect the whole system, because:

- The installed chiller will not totally stop due to excessive high pressure; due to the 1.2°C warmer water the chiller will unload and capacity will suffer, however it will not fail. The final result will be some loss of comfort, or in the case of industrial applications, some slowdown of the production process will take place.

- In typical Mid-European climates there will be less than 100 hours when the wet bulb temperature is higher than 19.3°C spread over a few summer days.

The underperformance may seem slight. In fact, there may be several years of bad summers, where design water temperature conditions are never exceeded. So why is it a big problem? The answer can only be found if we look at the annual economic impact. By comparing Model A and Model B we see that the fan kWh requirement for Model A will be 27770 kWh and for Model B it will only be 25400 kWh, due to the smaller fan motor. However, look at the electrical energy needed for the chiller: For the Model A we need 1,114,360 kWh, but for Model B the chiller requirement goes up to 1,178,700 kWh, which is almost 6% more. If we therefore add up the chiller and fan kWh, Model B still needs 5% more electrical energy on an annual basis.

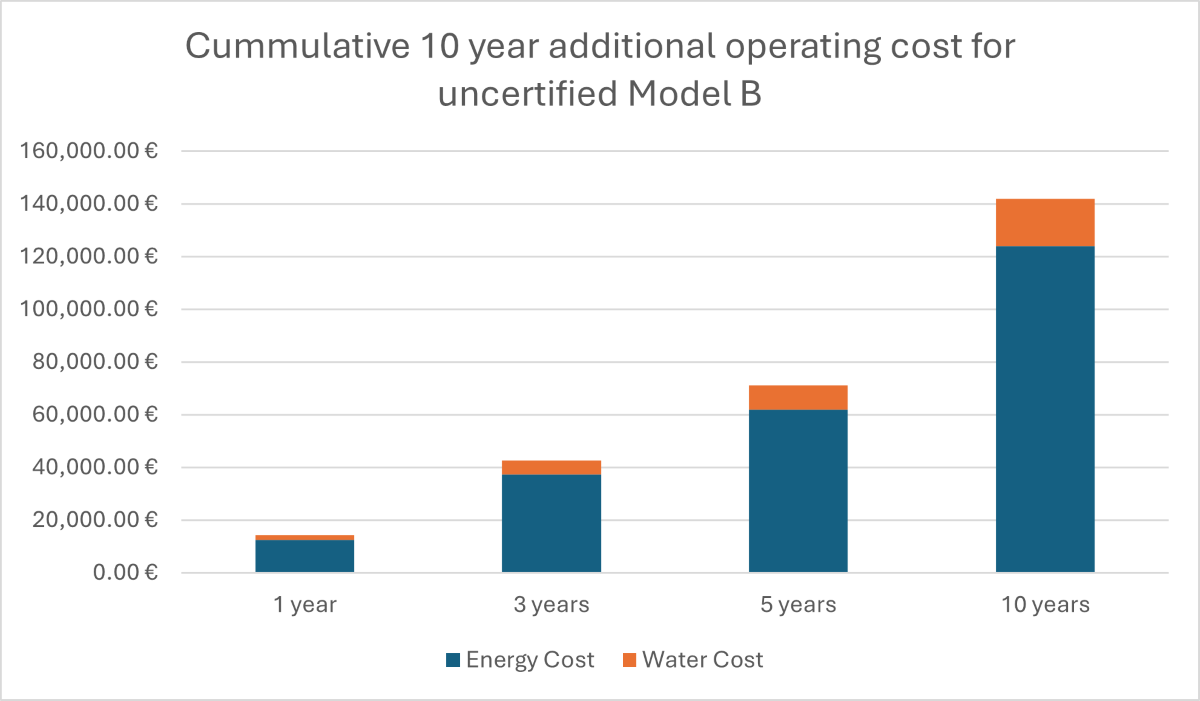

Example of additional operating costs for a non-certified cooling tower + Chiller = +€12,394/annum at a modest €0.20/kWh:

| Cooling tower + chiller (kWh) | Total (kWh & €) | Difference (kWh & €) | |

| Model A | Fan kWh = 27770 kWh + Chiller power = 1,114,360 kWh | 1,142130 kWh €228,426 |

0 0 |

| Model B | Fan kWh = 25400 kWh + Chiller power = 1,178,700 kWh | 1,204100 kWh €240,820 |

+ 61970 kWh €12,394 |

Note that energy prices have fluctuated wildly over the last couple of years. The increase kWh rate, at its peak in January 2023, would have seen a rate of €0.50/kWh = +€30,985 /annum!

But it doesn’t end there. In addition to electrical costs, there is more water consumption for Model B because the chiller has to work harder, hence more waste energy has to be dissipated and more water will evaporate. In our example, Model B will consume per annum 500m³ water more. If we take the very modest cost for water supply, sewage, and chemicals (€3.61/m³), this adds another €1,805 per year.

Conclusion: overall costs

The total additional annual operating cost for water and electricity for the system with Model B is €14,199. This is around half the initial cost of the new cooling tower, and shows that the small installation price advantage is a false economy. Long term, Model A offers a more energy efficient, effective, reliable and cost friendly choice.

Certified thermal performance testing guarantees performance and removes both risk and guess work to obtain system economics.

Find certified products

Eurovent Certification provides free, 24/7 access to transparent, accurate, universally understood performance data via its online Certified Product Directory. Whether you are considering a product that is new to the market, a brand you haven’t used before, or want to check the credentials of your ‘go to’ choice, you can use certified data to confidently compare products and make informed decisions.

Search HVAC and refrigeration products by product family, type, brand, model name or certificate number. If a product isn’t there, it isn’t certified.

Search the certified product directory now