News

2024 Drift Eliminator testing complete!

Discover more on Drift Eliminator Certified Performance and the 2024 testing completed for evaporative water-cooling equipment (worldwide).

By Mr Ian BUTLER, Drift Eliminator & Cooling Tower Programme Project Manager

Eurovent Certification is very pleased to announce the completion of its 2024 Drift Eliminator certification test campaign, which consisted this year of Counterflow Drift Eliminators; however, the capability exists to evaluate and certify Crossflow integrated & non-integrated Drift Eliminator types as well.

Testing has been conducted at the dedicated 4JTECH testing laboratory facility located in Prague, Czech Republic together with USA based McHale Associates Inc. a Cooling Technology Institute (CTI) licenced testing agency for Drift Eliminator testing. Testing used the Eurovent Certification technical certification rules ECP 14-DE-2023 for laboratory Drift testing and utilising the Heated Bead Isokinetic (HBIK) Drift test code ATC-140.

Initial validation of the 4JTECH laboratory had been conducted back in 2021 by McHale Associates prior to the last test campaign before this year’s.

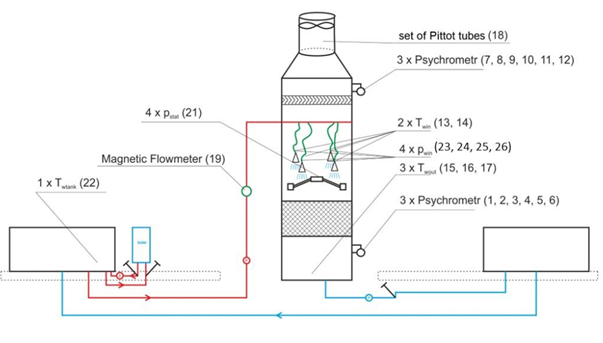

The 4JTECH Lab is a purpose-built tower for Drift and also Cooling Tower fill thermal performance research testing, here is an overview schematic of the tower, following the requirements of the ECP TCR 14-2023.

Diagram 1: 4JTECH Tower schematic showing feed hot water and return cold water tank including selected tracers; Lithium (Li) & Sodium (Na), together with the water flow metering, air monitoring equipment, water spray delivery nozzles and Isokinetic sampling train traverse monitoring collector device.

By utilising the same tower, measuring point locations and calibrated equipment, ensures the credibility and consistency of the test rig. Using an expert accredited ATC140 CTI licence test agency like McHale only adds to the accuracy and credibility of the test result data.

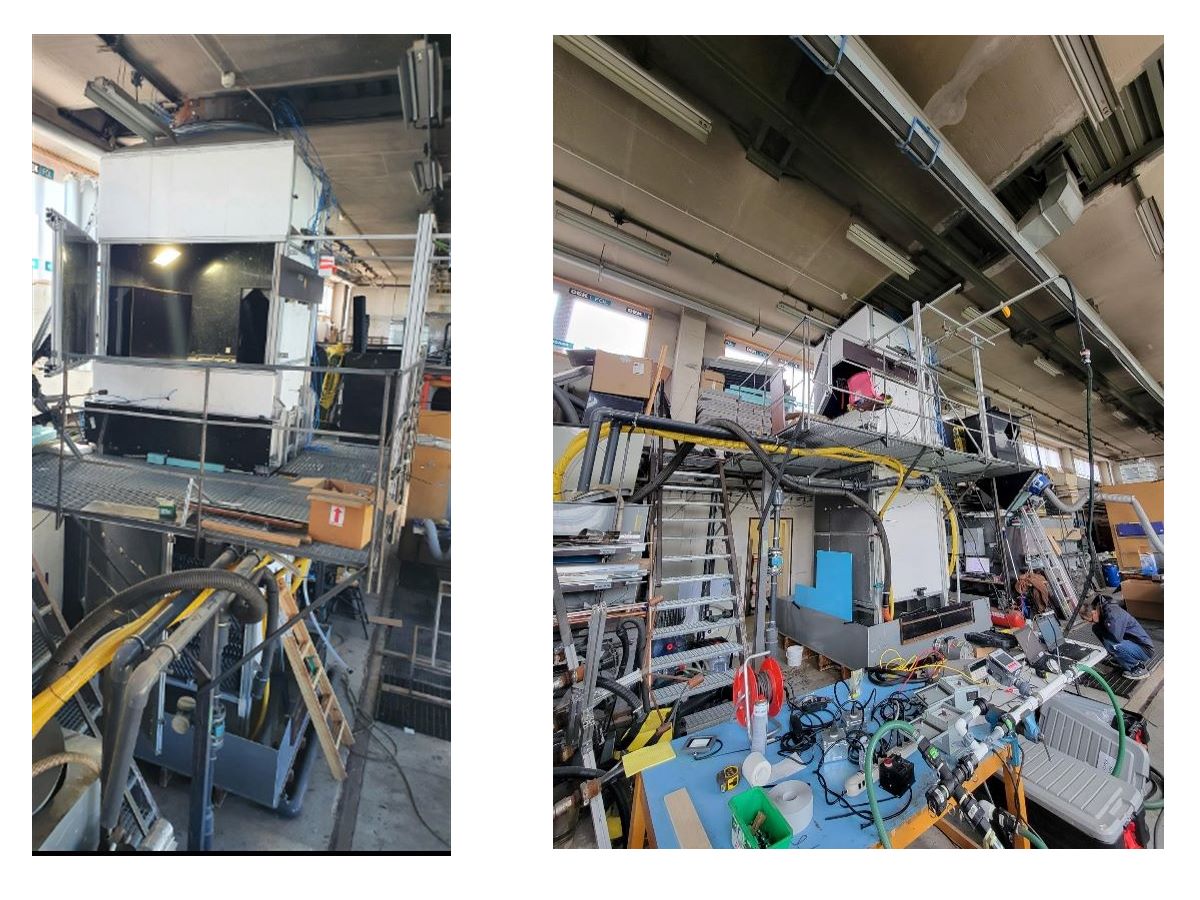

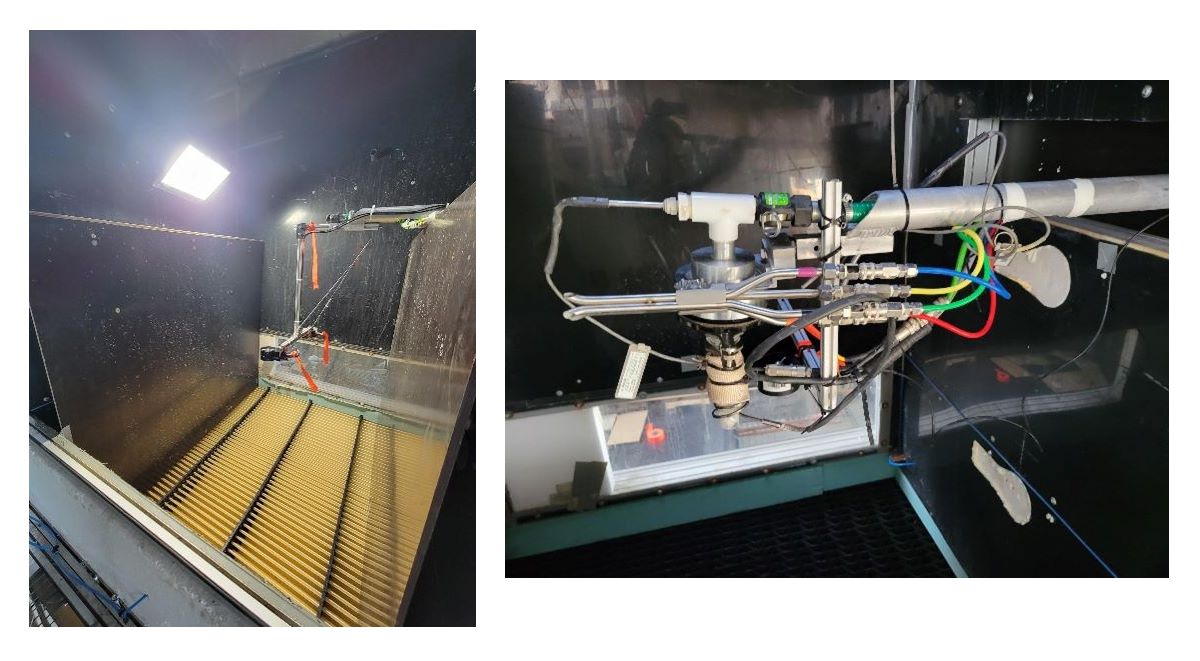

Here are some pictures to support the specialised work that 4JTECH & McHale work together to achieve, providing Heated Bead Isokinetic (HBIK) certified Drift performance data for its certification programme ECP-14-2023.

Pictures 1 & 2: Showing side on and front view of the tower, with key equipment on the test bench measuring / recording the required data.

Picture 3: Correct orientation of Drift materials is very important. Also important is to make sure that there are no side leaks around the Drift Eliminator tower inner walls, otherwise Drift bypass can be evident, which will invalidate the testing and provide very poor Drift rate results. Manufacturers can review with a video conference link up that their Drift has been installed correctly before testing is conducted. Videos can also be provided of the breakthrough velocity test, however, no results will be shared with the manufacturer until all results have been taken / validated and secondary reviewed by a secondary qualified McHale expert.

Pictures 4 & 5: With the Drift Eliminator in place and the traverse beam equipped with the Heated Bead Isokinetic (HBIK) head, Drift testing can begin.

The original scope of this certification programme had been developed back in 2009 by Drift Eliminator industry experts, utilising a controlled laboratory environment to obtain a Drift rate,* at specific controlled operating conditions for both air velocity and water loading, as well as the Drift breakthrough air velocity, which is the air velocity for which Drift losses become visible at any point of the Drift Eliminator, expressed in m/s. With a most recent update to Drift rate, test result declarations comply with LEEDs green building rating system.

*Drift Rate: Proportion of the drift volumetric flow rate to the circulating water flow rate entrained in the airflow and exiting at the discharge of the Eliminator, expressed as a percentage.

Drift Test demand: Drift Eliminator testing continues to be an increasing requirement to meet geographic governmental environmental regulations, not only in Europe but also worldwide. Such regulations to consider are; French norm NF E 38-424, incentive schemes i.e. LEED green building rating system and other industry needs. Therefore, Eurovent Certification is here to support the industry together with our testing experts McHale Associates Inc. and laboratory experts 4JTECH.

Eurovent Certification is a world leader in third-party certification, operating in the fields of Heating, Ventilation, Air conditioning and Refrigeration (HVAC&R), meeting the needs and requirements of an evolving industry in the residential, commercial, or industrial markets. Its historic certification mark, Eurovent Certified Performance, is well recognised around the world, with an international accreditation to ISO17065 the standard for Certification bodies.

If you have any Drift Eliminator or Cooling Tower testing needs, then please get in touch with Ian Butler, Programme Manager for Drift Eliminators (DE’s) and Cooling Towers (CT’s) by email or contact us via our how to apply page.