News

Programme focus: Heat Exchangers (HE)

Heat exchangers are an essential component in many commercial and industrial systems due to their ability to transfer and reject heat. They can be found in a range of critical applications for refrigeration and process cooling, including data centres and food cold chain, where precise, constant temperature control is required. System performance and reliability is therefore paramount in such projects, where system failure could be catastrophic.

The Eurovent Certified Performance programme for Heat Exchangers (HE) certifies five groups of products using axial flow fans. These include Direct Expansion (Dx) Air Coolers using HFC, Dx Air Coolers using CO2, Air Cooled Condensers, CO2 Gas Coolers and Dry Coolers.

Why is heat exchanger certification important?

Selecting the correct heat exchanger is essential, or the energy efficiency and reliable operation of the whole system could be compromised. To help make the right choice, decision makers must have access to accurate product data, to ensure products perform as advertised.

However, product data is not always correct. Heat exchangers can be particularly vulnerable to deviations between the performance stated and operation in real life because they are complex products to test. For example:

- Heat exchanger geometry, materials, angles of fins, and type have a considerable impact on the heat transfer coefficient, even when using the same total heat exchange area.

- Self-declared manufacturer data can also lead to discrepancies. Variations in self-assessment testing facilities, test equipment calibration, processes and procedures, plus unintentional bias, can unintentionally skew test results.

Therefore, it can be difficult to choose and compare heat exchangers that have not been through a common testing regime.

This is where the Eurovent Certified Performance programme for Heat Exchangers steps in. It offers decision makers assurance that product data has been independently and impartially verified by a robust and comprehensive certification process. Products that are successfully certified have been so thoroughly evaluated, that the certification offers a guarantee of performance. Eurovent Certification also ensures that products continue to comply with declared data via an ongoing surveillance process.

What products are included?

The heat exchanger programme is open to:

- Direct Expansion (Dx) Air Coolers using HFC

- Dx Air Coolers using CO2

- Air Cooled Condensers

- CO2 Gas Coolers

- Dry Coolers.

What is certified?

For the admission process units are selected by Eurovent Certification and tested in an Independent Laboratory and undergo a factory audit. For the surveillance procedure units are selected from regular production and tested on a yearly basis.

Certified performances and their acceptance criteria:

- Standard capacity –8%

- Fan power input +10% with a minimum of 3 W

- Air volume flow ±10%

- Energy ratio R

- Energy class.

For Dry Coolers:

- Liquid side pressure drop +20% with a minimum of 5 kPa.

For Air Cooled Condensers and Dry Coolers:

- A-weighted sound power level: +2 dB(A).

In addition, before carrying on tests, the coil dimensions and fins information are checked. Their acceptance criteria are the following:

- Finned length ±0,5%, with a minimum of 5 mm

- Height of the coil ±5 mm

- Depth (width) of the coil ±5 mm

- Total number of fins* ±4%, at least 2 fins

- Diameter of (expanded) tube outside the coil* ±1 mm.

(*) except for the micro-channels.

What are the testing standards?

Heat exchangers certified under this Eurovent Certified Performance programme are tested to:

- EN 328:2014: For Direct Expansion (Dx) Air Coolers

- EN 327:2014: For Air Cooled Condensers and CO2 Gas Coolers

- EN 1048:2014: For Dry Coolers

- EN 13487:2019 and EN ISO 9614-1: 2009 Acoustics.

You can find out more about the certification rules and requirements in the Technical Certification Rules and Certification Manual on our Eurovent Certified Performance programme for Heat Exchangers page.

The white paper, “Broken trust: Energy efficiency and the refrigeration industry,” has probed the problem of product underperformance in the European refrigeration sector. With all industry players requiring accurate and reliable product information, the white paper draws on new research which reveals a potential 31% gap between a product’s claimed and expected performance.

Focusing on the importance of reliable data and the impact of discrepancies on all industry players, the white paper investigates the causes of data inaccuracy and the resulting impact on energy efficiency. Discover the key headlines from the latest research and crucially, the solutions and recommendations to ensure a match between an installed product’s claimed and expected performance.

Are you taking a gamble on refrigeration equipment?

Why choose Eurovent Certified Performance?

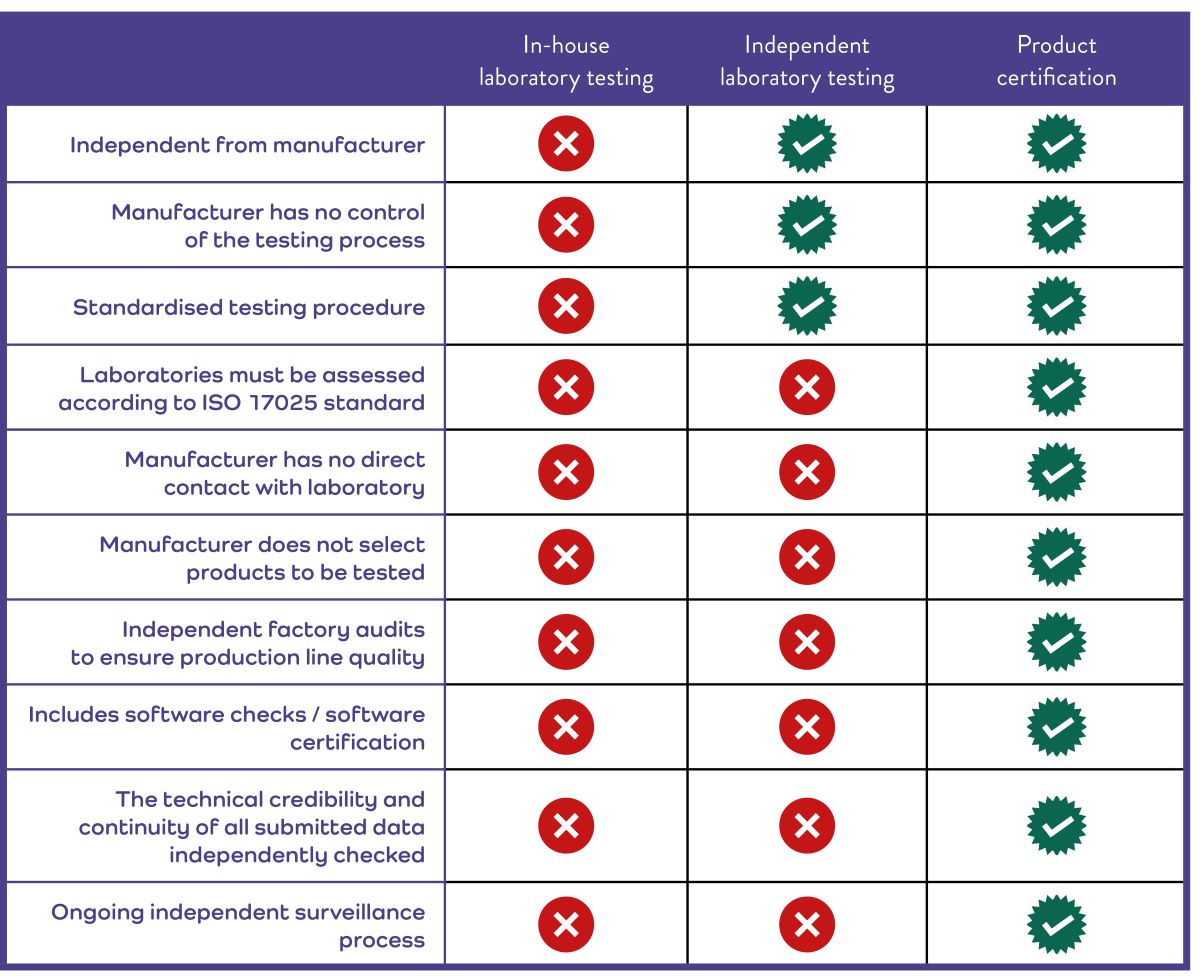

Eurovent Certified Performance for Heat Exchangers offers a comprehensive, independent and impartial certification programme, which goes far beyond laboratory testing alone.

This programme includes:

- Independent laboratory tests

- Factory audits

- Software audits

- Full analysis and validation of all supplied data (including marketing materials)

- Surveillance process to ensure continued conformity.

Evaluation protocols are uniform to ensure the certification process is fair and equal for all manufacturers. Eurovent Certification:

- Evaluates each heat exchanger type according to the same criteria

- Expresses results in the same unit of measurement, regardless of the country where the products are manufactured or marketed

- Ensures all products within the programme go through exactly the same certification, auditing and surveillance process

- Ensures products with components manufactured across multiple sites (sometimes in different countries), all reach Eurovent certification standards

- Impartiality standards are kept high as manufacturers and laboratories have no direct contact, keeping the process clear of any bias.

As heat exchangers go through the same process, decision makers can directly compare this data when making product decisions, via the free to access certified product directory.