News

Programme focus: Air Handling Units (AHUs)

The Eurovent Certified Performance programme for Air Handling Units (AHUs) is one of our largest and most established programmes. The programme attests the conformity of air handling units to European Standards and provides independently verified product performance data via an impartial and vigorous certification process.

Why is AHU certification important?

The best designed and installed systems will underperform if expected product performance does not match manufacturer claims.

Air handling units often have very succinct requirements, which means decision makers need accurate information to be able to compare and select the ideal unit. Many aspects will affect product selection and while installation costs will be a factor, lifecycle costs, carbon footprint and energy efficiency are playing an increasingly important role. It’s imperative the AHU meets any cooling, heating and ventilation requirements or it will underperform. The installation space itself may have size constraints, or limitations on sound levels if noise could be an issue. Likewise ongoing maintenance and the replacement of filters must be considered. Of course, units must also comply with regulations.

If manufacturer data is inaccurate, resulting in a poor choice of equipment, it can spell disaster for the end user, and all those involved in the system’s specification, design installation and ongoing maintenance. Third-party evaluation via Eurovent Certification removes the risk of incorrect product data.

What products are included?

This certification programme applies to all ranges of AHUs that can be selected in a software. Products eligible to undergo the certification process include:

Model Box: The model box is the construction envelope of the AHU, built according to specifications presented in manufacturer’s literature. In the AHU programme, model box testing is used to establish mechanical, thermal and acoustical performance according to the relevant EN standards.

Real Unit, reversible, with heat recovery: An AHU of a specific size, with both heating and cooling, and heat recovery, is used to establish performance for all the available functions of the AHU range.

Real Unit, heating only, without heat recovery: An AHU of a specific size, with a heating only function, without heat recovery, is used to establish performance for all the available functions of the AHU range.

Real Unit, reversible, without heat recovery: An AHU of a specific size, with both heating and cooling, without heat recovery, is used to establish performance for all the available functions of the AHU range.

All Real Unit AHU tests are undertaken in accordance with the relevant EN standards.

All products in a range must be certified. Each declared range shall at least present one size with a rated air volume flow below 3 m²/s. For each declared range, all Real Unit sizes available in the software and up to the maximum stated air flow and all Model Box configurations are considered. All configurations have to be made known for certification.

What is certified?

For the admission procedure, model boxes in different configurations will be tested and a visit to the production site will be organised. During that visit:

- The selection software will be verified by our internal auditor including the energy efficiency classes.

- The auditor to review factory product area for Component verification, and Model Box consistency check against the last Model Box report.

- The auditor will select one Real Unit per range.

- The selected units will be tested, and performances delivered by the selection software will be compared to the performances measured in an independent laboratory.

For the surveillance procedures, the auditor will annually check the software conformity against the production data during a factory audit, and tests will be repeated every three years for the real unit. Retesting of the model box is required if the unit undergoes changes or is new to certification.

The following mechanical characteristics are certified:

a - Casing strength (CS)

b - Casing air leakage (CAL)

c - Filter bypass leakage (FBL)

d - Thermal transmittance of the casing (TT)

e - Thermal bridging factor (TBF)

f - Acoustical insulation of casing

The following performance characteristics are certified:

a - Air flow - Available static pressure - power input

b - Octave band in-duct sound power level

c - Airborne sound power level

d - Cooling capacity**

e - Heat recovery temperature dry efficiency **

f - Heat recovery humidity efficiency**

g - OACF and EATR**

h - Pressure loss on water side**

i - Heat recovery pressure drop on both air sides

j - For run-around coils, fluid side pressure drop, glycol percentage and absorbed motor power of the circulation pump (if pump rated in output)

k - Calculated Eurovent AHU Energy Efficiency Class.

** If standard features of the product range

Plus, energy efficiency labelling for the AHU programme includes:

- Energy efficiency class for winter application

- Energy efficiency class for summer application.

What are the testing standards?

AHUs certified under this Eurovent Certified Performance programme are tested to:

- EN 1886:2007 “Ventilation for buildings – Air handling units – Mechanical performance”

- EN 13053:2019 “Ventilation for buildings – Air handling units – Rating & performance for units, components and sections”

- Appendix H of ECP-05 AHU for HAHU.

You can find out more about the certification rules and requirements in the Technical Certification Rules and Certification Manual on our Eurovent Certified Performance programme for Air Handling Units page.

Hygienic option

There is an option for AHUs in an already certified range, to also be certified as “hygienic”. Hygienic AHUs provide the same functions as traditional AHUs but are suitable for applications requiring a high hygienic standard. The hygienic aspect of the AHU is certified based on 3 levels of classification, dependent on different applications:

Level 1: Is suitable for commercial applications including offices, commercial buildings, schools and hotels.

Level 2: Is suitable for use in hospitals and healthcare. Level 2 certified hygienic AHUs comply with the VDI 6022-1:2018 standard.

Level 3: Is suitable for applications including pharmaceutical, food processing, white rooms, operating theatres and equivalent. Level 3 certified hygienic AHUs comply with the VDI 6022-1:2018 and DIN 1946-4:2018 standards.

Find out more about our hygienic AHU certification.

In 2024, the programme underwent two big improvements with the introduction of a new test methodology and new energy class calculations. These changes were enacted to streamline the process for manufacturers, while ensuring the tests were more representative of actual performance. For the 2025 campaign onwards, if no Eurovent-certified filters are selectable in the software, an additional test is required to test the filter ISO efficiency of the selected filter. Find out more in our interview with Programme Manager, Donatien Lambert: What’s new for AHUs.

⚠️ Recent changes to the Hygienic AHU programmeFrom 2025, the hygienic option requirements has been modified. This new release aims to comply with VDI 6022-1:2018 and DIN 1946-4:2018 standards:

- Level 2 certified hygienic AHUs comply with the VDI 6022-1:2018 standard.

- Level 3 certified hygienic AHUs comply with the VDI 6022-1:2018 and DIN 1946-4:2018 standards.

Why choose Eurovent Certified Performance?

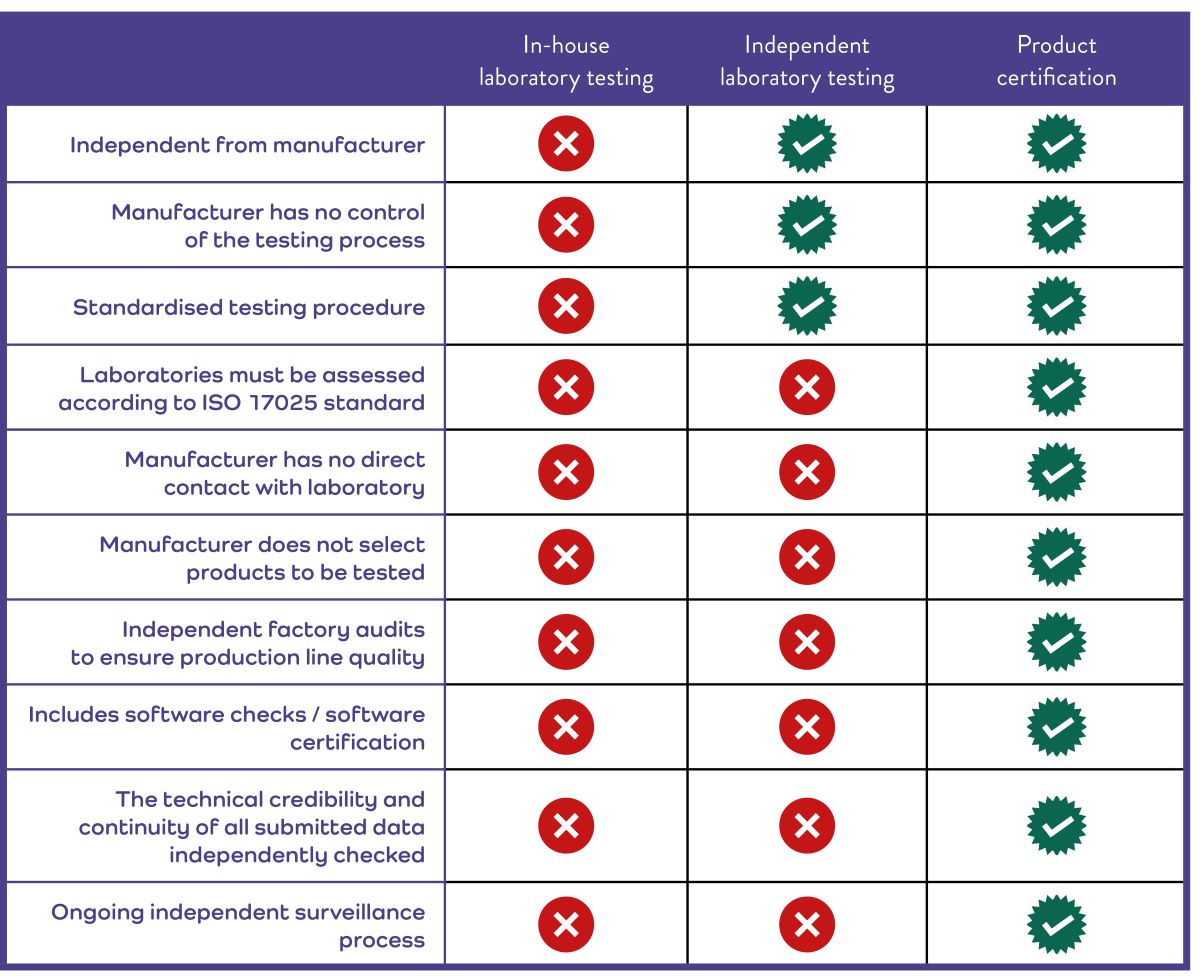

Eurovent Certified Performance for AHUs offers a comprehensive, independent and impartial certification programme, which goes far beyond laboratory testing alone.

This programme includes:

- Independent laboratory tests

- Factory audits

- Software audits

- Full analysis and validation of all supplied data (including marketing materials)

- Surveillance process to ensure continued conformity.

Evaluation protocols are uniform to ensure the certification process is fair and equal for all manufacturers. Eurovent Certification:

- Evaluates all AHUs according to the same criteria

- Expresses results in the same unit of measurement, regardless of the country where the products are manufactured or marketed

- Ensures all products within the programme go through exactly the same certification, auditing and surveillance process

- Ensures products with components manufactured across multiple sites (sometimes in different countries), all reach Eurovent certification standards

- Impartiality standards are kept high as manufacturers and laboratories have no direct contact, keeping the process clear of any bias

- Additionally, products to be tested can be taken from the production line, factory stock or point of sale, ensuring the product tested is exactly the same as those leaving the production line.

As all AHUs go through the same process, decision makers can directly compare this data when making product decisions, via the free to access certified product directory.