Influence of the Dry Cooler Capacity on the Efficiency of Chillers

Increased energy efficiency through certification

Authors : Dipl. -Ing. Hanns Christoph Rauser - HCR CONSULTING - Germany

Stefano Filippini - Chairman of the Compliance Committee for Heat Exchangers

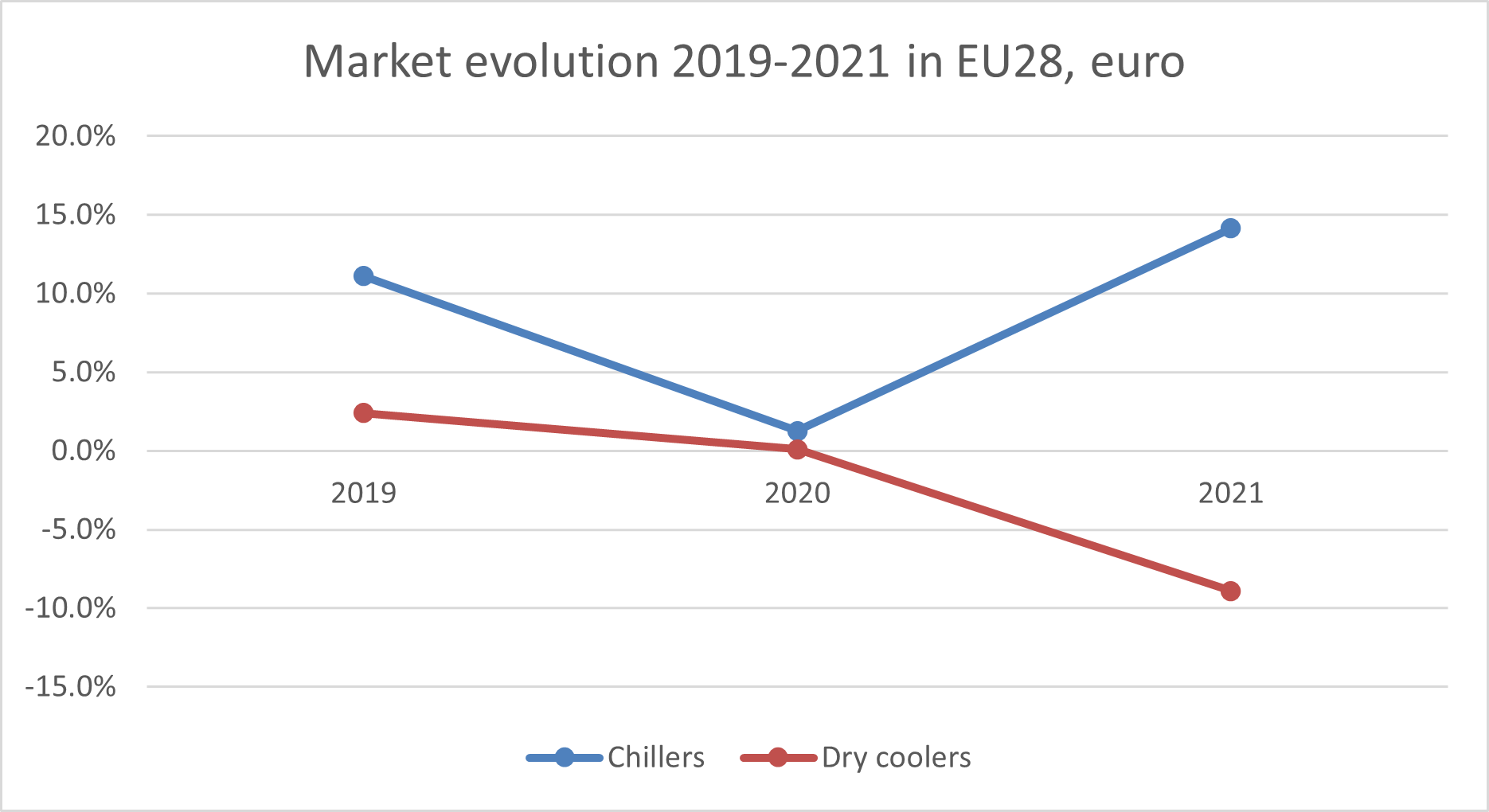

While EcoDesign has forced Chiller technology to improve significantly over the years, energy savings can be further enhanced by the addition of dry coolers. However, a recent drop in dry cooler sales, shows that many new chiller installations are missing out on important energy and financial savings.

Chiller systems have to hit Minimum Energy Performance Standards (MEPS) and have separate performance requirements depending on chiller type and application. Ensuring systems go above and beyond MEPS brings lower running costs, less environmental impact, and possible future proofing against further legislation.

To allow for energy efficient system design, manufacturers have to provide EcoDesign data by law. However, not all data is equal and for the professional, navigating between certified and un-certified products can be a minefield. For example, between 2004 and 2008, Eurovent Certita Certification (ECC) was asked by the ECC certified heat exchanger manufacturers, to independently test the performance of nine heat exchangers. These were manufactured by seven European companies, not participating in the Eurovent certification programme. A comparison of the performance data tested, with the values published in the manufacturers' product literature, resulted in a capacity reduction up to 37%. Truly energy efficient systems can only be designed with the correct information.

How do dry coolers improve efficiency?

Dry coolers are essentially heat-transfer devices that use forced air convection to remove excess heat. Also known as air coolers, the technology can be used to cool water in the water condensers of chilled water production units, or for free cooling applications. Dry coolers can help decrease the load on the chiller system, by removing process heat and reducing the work of the compressor.

The main components of dry coolers include an air to liquid heat exchanger and fan blower. Dry coolers are a closed circuit system, using fans to pull in ambient air. This air flows over a heat exchanger, which can either be a traditional fin and tube design or microchannel. The air passing over the heat exchanger attracts heat from the fluid within, which is typically water or a water-glycol mix. Once cooled, the fluid is ready to absorb heat from an associated process. Once it has done this, the fluid returns to heat exchanger to begin the cycle again.

Dry coolers are suitable for high cooling capacities, in regions where the ambient air temperature is cooler that the water / water-glycol mix in the system. Even if the air temperature is cooler for only part of the year, savings will be made. When using a certified chiller with a separately installed condenser or recooler, it is advisable to use a certified product in order to reach the maximum energy efficiency.

Chiller Construction Types

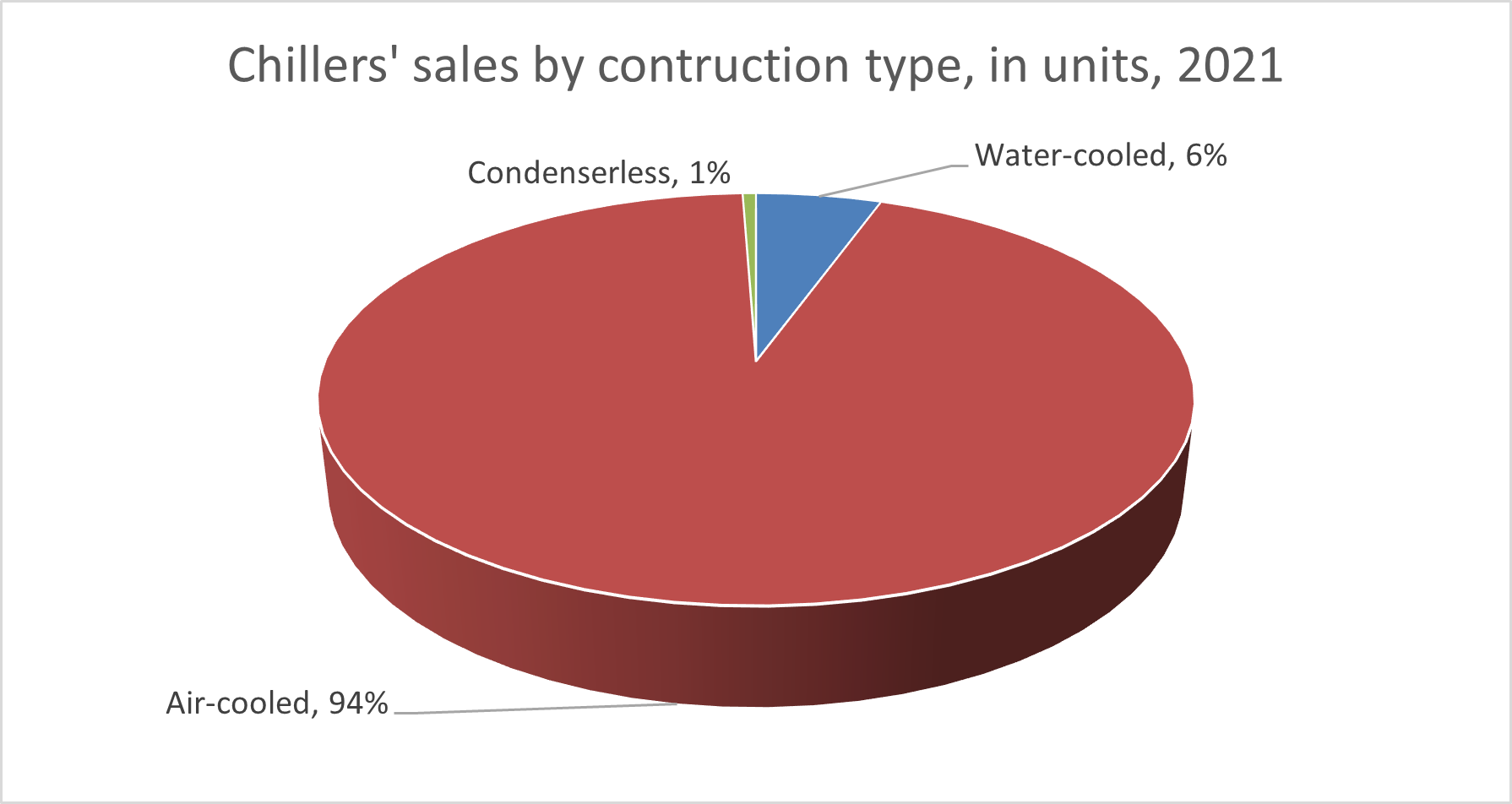

Water-cooled chillers are built with plate and tube bundle heat exchangers as condensers. In these systems the heat is dissipated into the ambient air by a recooler in the secondary cycle. If the heat is being dissipated directly into the ambient air by a condenser, the system is called air-cooled chiller. These are classified as either a compact chiller for outdoor use with integrated air-cooled condenser, or a chiller split system with an air-cooled condenser for outdoor installation. Today, in most cases, compact air-cooled chillers are used.

The chiller market

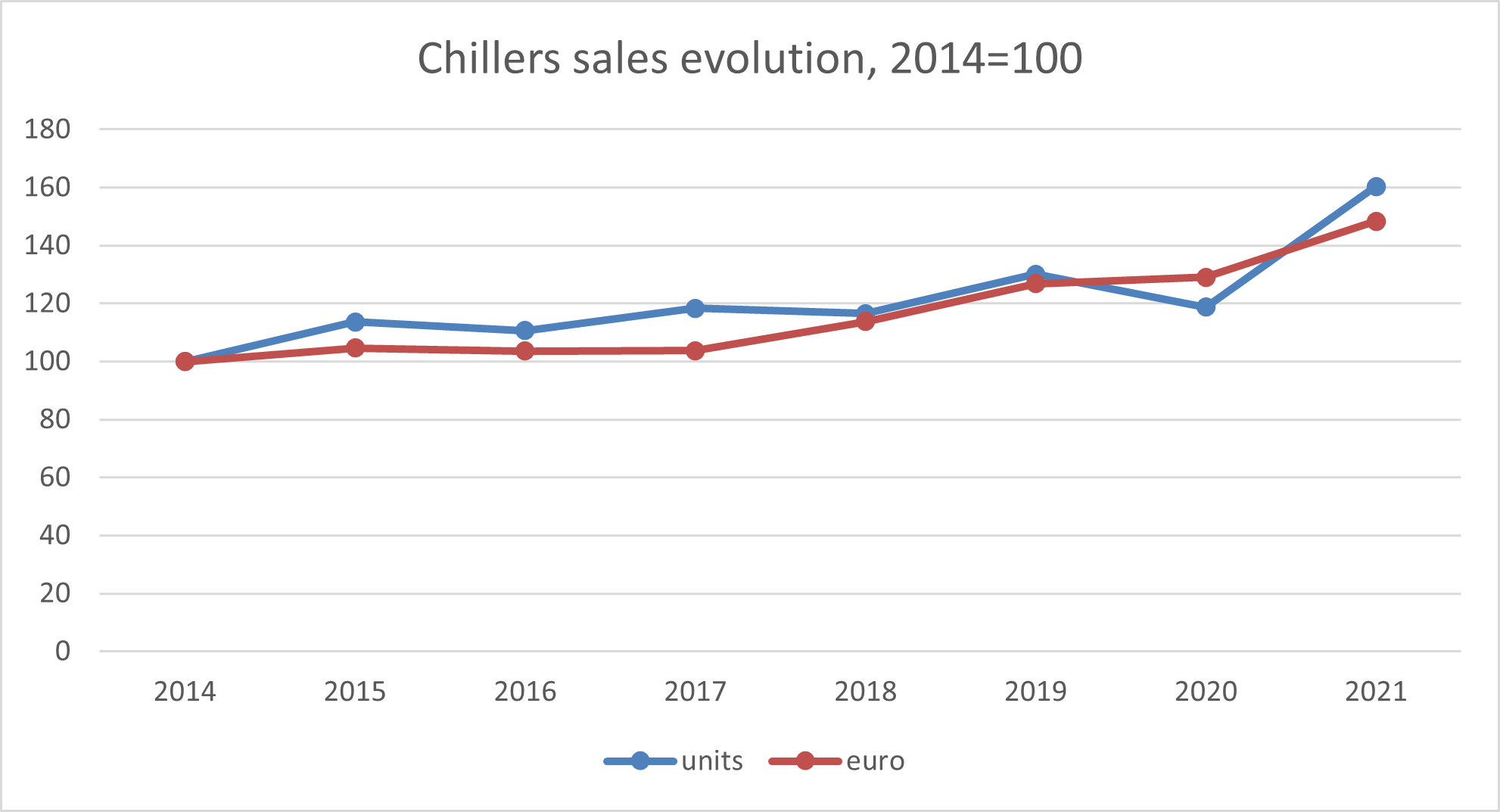

Most chillers are certified by Eurovent Certita Certification. Currently 33 chiller manufacturers participate in the Certification Programme. The chillers' sales evolution in the EU from 2014-2021 is shown in Figure 1, while the evolution of chiller vs dry cooler sales is shown in figure 2.

Figure 1: Chiller’s sales evolution, 2014-2021, from Eurovent Market intelligence.

Figure 2: Chiller and dry cooler sales evolution in EU28, 2019-2021, from Eurovent Market intelligence.

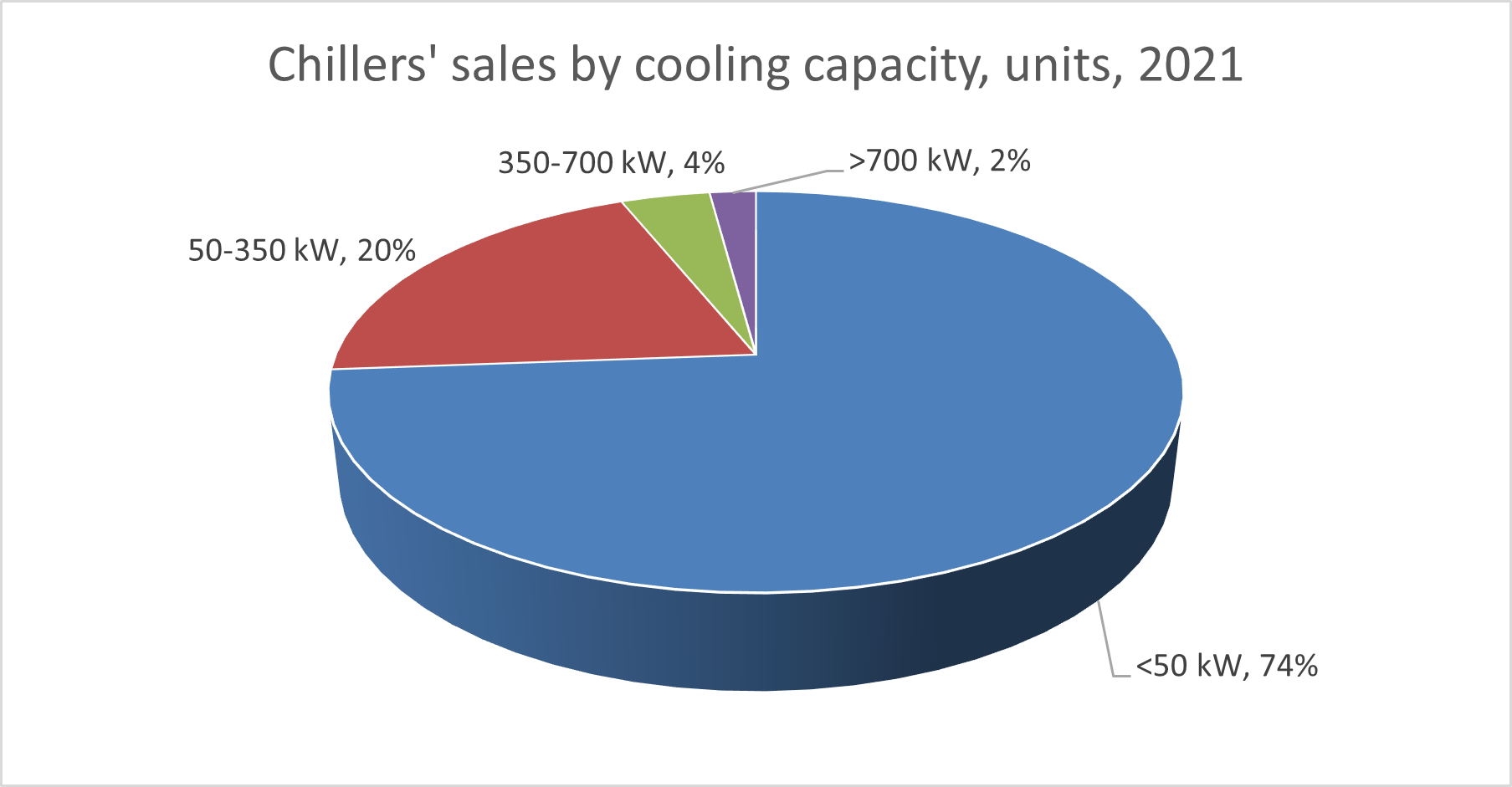

The EU chiller sales proportion in 2021 according to construction type and size is shown in Figures 3, 4 and 5.

Figure 3: Chiller sales by construction type, EU 28 – 2021, from Eurovent Market intelligence.

Figure 4: Chiller sales by cooling capacity (percentage of units), EU 28 – 2021, from Eurovent Market intelligence.

Figure 5: Chiller sales by cooling capacity (percentage in kW), EU 28 – 2021, from Eurovent Market intelligence.

Calculation Model

Two test systems were set up to measure the influence of the dry cooler on the energy efficiency of a whole water-cooled chiller system. One used a certified dry cooler, the other a non-certified dry cooler.

The chiller system comprised of a Eurovent certified water-cooled chiller, of Eurovent energy efficiency class B, used for air conditioning (cooling only). The cooling capacity of 1000kW at full load, and ambient temperature 35°C, was provided by two screw compressors using refrigerant R134a. The evaporator cooled down water from 12°C to 7°C.

In the simplified model it was assumed that the temperature difference between condensing temperature and ambient temperature was a fixed 12K. The condenser heated up the secondary fluid, which was recooled by a dry cooler. In the dry cooler the secondary fluid was cooled down by 5K to a temperature that was 5K above the ambient temperature. The pump power of the secondary fluid was not considered. The study had a capacity gap of 25%.

At full load the non-certified dry cooler caused a 2.5K higher condensing temperature of the chiller. At 75%, 50% and 25% part load operation, the AC fan speed of the non-certified dry cooler was raised to achieve the same condensing temperature as when using the certified dry cooler. Both systems were compared using the ESEER (European Seasonal Energy Efficiency Ratio) value of the complete system.

Results

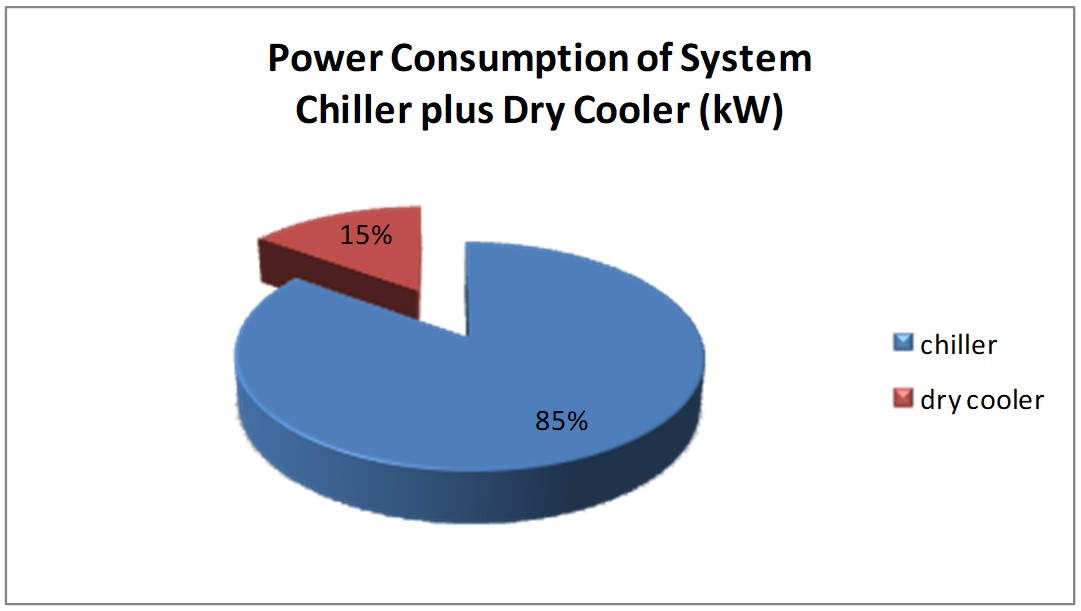

The dry cooler fan power consumption was within the range of 10% and 20% of the total system's power consumption at the different load conditions (Figure 6).

Figure 6: Power consumption of the total system chiller plus dry cooler (kW), from Eurovent Market intelligence.

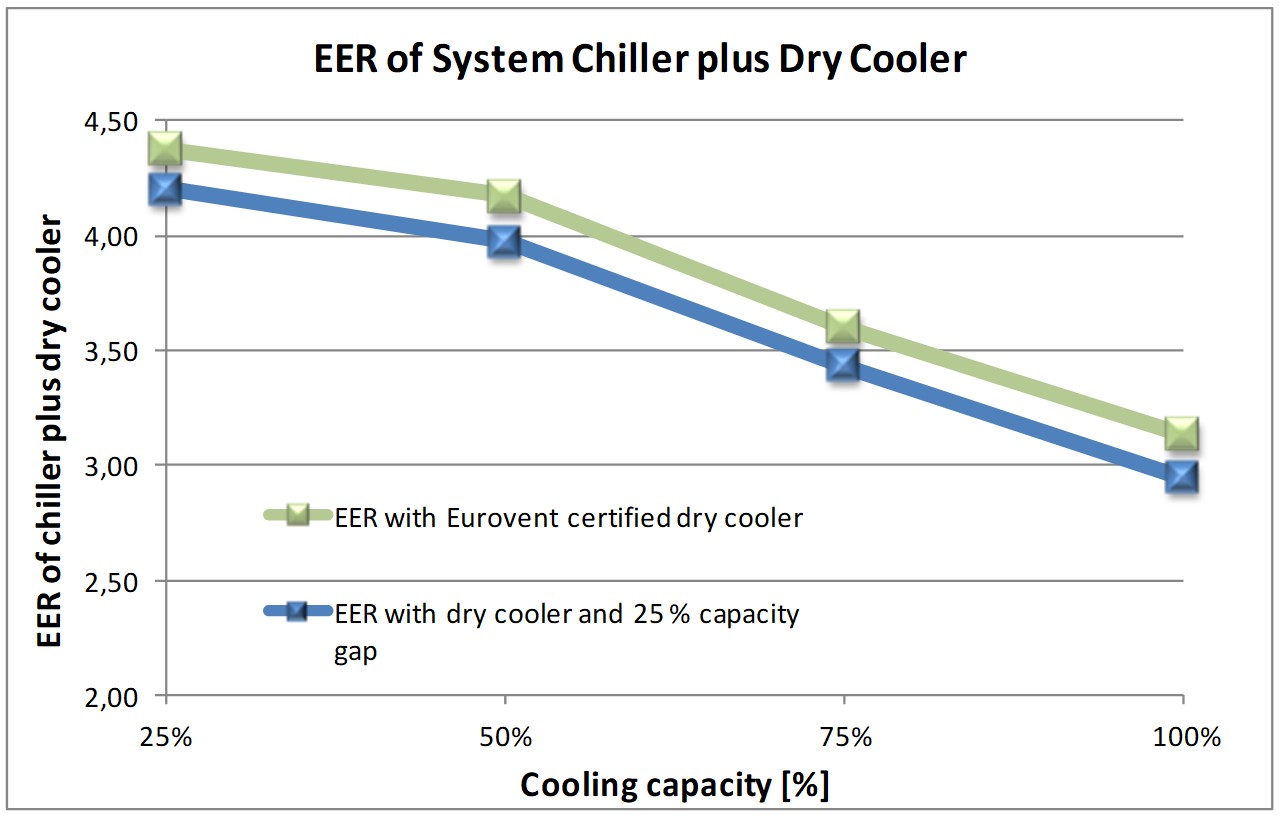

Figure 7 shows the Energy Efficiency Ratio (EER) of the total system with the two different dry coolers. The ESEER value of the system using a dry cooler with capacity gap is 4.6% lower, due to the higher power consumption of the chiller at full load, and the higher power consumption of the fans of the dry cooler at part load operation.

To put this into context, for the City of Milan, the annual energy saving of the chiller system using a dry cooler, obtaining the designed capacity, is around 20,000 kilowatt-hours at a calculated 3542 operating hours.

At energy costs of 0.15€ (£0.12) per kilowatt-hour the saving in energy costs will be around 3000€ (£2500) per year. Assuming that a non-certified dry cooler may be 10% cheaper, the payback time is less than 1.7 years and every year annual savings in operating costs will be achieved. Additionally capacity gains or benefits when for example operating with free cooling are possible.

For chillers with longer operating hours, or chillers designed for process cooling, the payback time will be even shorter.

Figure 7: EER of system chiller plus dry cooler at different load, from Eurovent Market intelligence.

Why certification is important

The results show how important it is to use certified components and systems. Correct performance data for heat exchangers is absolutely essential, because it influences the energy efficiency of the entire system. In the study, a water-cooled chiller, recooled by a non-certified dry cooler with a capacity gap of 25%, was causing 4.6% higher energy costs.

This is why when using a certified chiller with a separately installed air-cooled condenser or dry cooler, you should use a certified product in order to reach the maximum energy efficiency. It will save money and energy in the long term and you can rest assured that certified products will work as intended.

To view and compare certified products such as chillers and dry coolers, our easy to use certified product directory can help. Search products by family, type, brand, model name and certificate number.

Search for certified products now