Case study: Overestimated performance of CO2 gas coolers

CO2 gas coolers are growing in popularity and for good reason. With HFC refrigerants being phased down in the heat exchanger market due to their high Global Warming Potential (GWP), the refrigerant R-744 (CO2) is becoming a serious alternative to eliminate the greenhouse effect caused by the halogenated carbons in HFCs refrigerants. In addition, R-744 is a non-toxic, non-flammable, and natural refrigerant.

However, in the race to embrace green technology, we need to remember how important it is that specifiers and system designers have access to reliable data on real-life system capabilities, so that systems are successfully designed and installed, operating as specified. If not, the reputation of the technology (and those who specify, design and install it) can be unfairly damaged, when supposedly sustainable systems do not operate as expected.

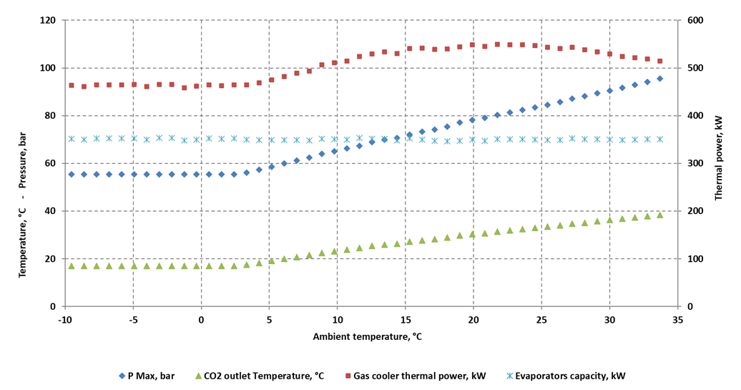

Deviancies in claimed and real performance cause big problems. And so, investigations were undertaken on the impact of an overestimation of CO2 gas cooler performance on the efficiency of the refrigeration plant, specifically on the system’s annual power consumption and its related cost. Simulations were performed to estimate the efficiency of the thermodynamic cycle, coupling some theoretical and empirical rules to the rated thermal capacity of the CO2 gas cooler. The comparison was made between a Certified CO2 gas cooler (Case Study 1) and an uncertified CO2 gas cooler (Case Study 2). The main assumptions for the simulations were:

- Two temperature levels:

- Medium temperature (MT): Tevap, MT = -8 °C; Qevap, MT = 250 kW

- Low temperature (LT): Tevap, LT = -30 °C; Qevap, LT = 100 kW

- Design ambient temperature: 35°C

- Maximum operating pressure: 95 bar

- Design gas cooler capacity (SC20) = 490 kW

- Electricity specific cost: 0,25 €/kWh.

Case study 1: Certified CO2 gas cooler

The simulation was performed on a certified unit with a design capacity in line with the real performance of the CO2 gas cooler. The following results were obtained:

| Case study 1: Economic simulation considering an energy cost of 0.25 €/kWh | |

| Plant consumption | 1.456 MWh/year |

| Gas cooler fans’ electricity cost | 8.134 €/year |

| Compressor electricity cost | 355.746 €/year |

| Total cost | 363.880 €/year |

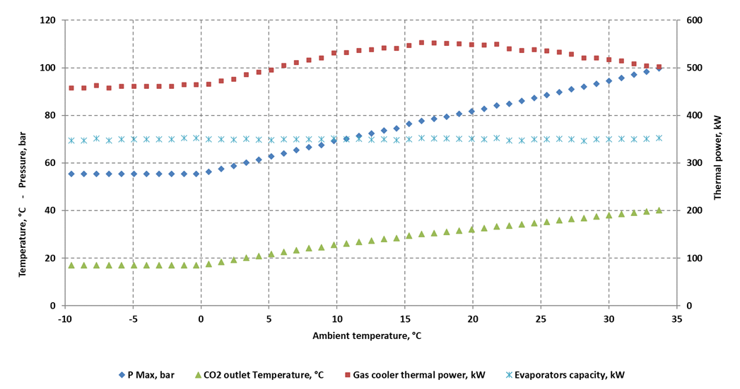

Case study 2: Uncertified CO2 gas cooler

The second simulation is for an uncertified CO2 gas cooler, with a design capacity higher than the real capacity. In this instance, the uncertified manufacturer applied a 25% oversizing coefficient, which resulted in a real thermal capacity lower than the declared one.

In this case, the compressor had to compensate for the lack of capacity of the gas cooler, to keep the useful effect at the evaporators as expected. Additionally, the maximum pressure reached by the system in the design condition is over 99 bar, more than 4 bar higher than the design maximum pressure.

| Case study 2: Economic simulation considering an energy cost of 0.25 €/kWh | |

| Plant consumption | 1.518 MWh/year |

| Gas cooler fans electricity cost | 8.633 €/year |

| Compressor electricity cost | 370.824 €/year |

| Total cost | 379.457 €/year |

While the difference between the 2 simulations may appear insignificant, the effect on the annual consumption and therefore cost, is absolutely non-negligible:

| Summary of consumption and cost increase due to the use of uncertified CO2 gas cooler | ||

| Plant electricity consumption | +4.2% | 62 MWh/year |

| Gas cooler fans electricity cost | +6.1% | 499 €/year |

| Compressor electricity cost | +4.2% | 15.078 €/year |

| Total cost | +4.3% | 15.577 €/year |

The annual cost increase in a gas cooler with a capacity 25% lower than expected is therefore around 15.600€, resulting in 156.000€ over a 10-year lifetime. The higher the gap between declared and real gas cooler capacity, the higher the impact on plant energy consumption. When it comes to long-term costs and sustainability, the benefits of choosing products with Eurovent Certified Performance is clear.

To find certified gas coolers please visit www.eurovent-certification.com

For more information on the ECP Heat Exchangers programme, please contact Japhet HABIMANA at j.habimana@eurovent-certification.com.