What is an air handling unit (AHU)?

Studies have shown that around 90% of people spend 90% of their time indoors. It’s easy to assume that we’re safe inside our homes and offices. We all know about outdoor air pollution and the hazards of life in the big city.

But the truth is that indoor air pollution is a rising concern and has been reported by the US Environmental Protection Agency (EPA) as one of their top five environmental risks.

So, it makes sense to invest in an air handling unit that can control not only the thermal comfort of a building but also other features such as air filtration, humidification, and ventilation. In the past, only the thermal requirements were considered.

These days, as people are more aware of the dangers of indoor air pollution and the harmful health effects of particulate matter (PM) in the environment, air handling units have evolved and become more advanced.

However, as our knowledge on air pollution rises, so does our awareness of a need to be energy efficient and ensure that we are reducing our energy consumption where possible.

Choosing an AHU which not only delivers on quality, but also eco-friendly credentials, can be a difficult task. With different global manufacturers all using their own methods of measuring and displaying key metrics, it can be difficult to ascertain the most important and necessary parameters.

This is where Eurovent can help. Eurovent has introduced a set of criteria for certifying and rating air handling units. With this system, consumers can make an educated and more suitable purchase of equipment for their indoor spaces.

The criteria for certification are discussed in more depth later on in this article.

By using this certification to assess and compare air handling units, you can be sure to choose a highly efficient machine that suits the building for which it is required.

How does an air handling unit work?

An air handling unit is a complex device that is designed to condition the air that is processed in heating, ventilation, and air conditioning systems, commonly known as HVAC. An AHU generally comprises a fan or fans and at least one other component for processing the air, such as a filter, heater, cooler, energy recovery component, humidifier, dehumidifier, or mixing section.

While this might seem complicated, each component works with the others to create a healthy and comfortable habitable area inside a building.

Continuously rising requirements for energy efficiency and indoor air quality (IAQ) in modern buildings, along with European Union (EU) legislation such as Ecodesign, have increased even the most basic requirements for air handling units.

To satisfy the requirements of the EU market, a modern air unit usually consists of fans, energy recovery devices, filters, heating and cooling elements, and a control device. The legislation evolving around energy efficiency has also led to improved fans and more efficient energy recovery devices.

How do you classify an AHU?

There are numerous ways to create a distinction between different AHUs, and the most common are described below.

By the direction of air movement: Unidirectional or bidirectional

An AHU can be unidirectional or bidirectional. As you might surmise from the names, a unidirectional ventilation unit is used to move the air in one direction only, and usually comprises a fan, filter, and a heating or cooling component. Meanwhile, a bidirectional unit can supply air to, and extract air from, the interior of a building.

By their structure: Compact or modular

A compact AHU is a system installed in one casing that usually features ventilation components such as fans, filters, and an energy recovery system. The benefit of this type of AHU is that it requires a much smaller installation space than a modular system. However, it is often not as wide-ranging in its performance, and other components, such as heating or cooling coils may need to be installed as duct accessories.

Modular air handling units provide much more flexibility in terms of their structure, arrangement of modules, dimensions, and specialised functions such as humidification and dehumidification. Each of the individual components are fine-tuned to work as part of the ventilation system and with custom AHU selection software.

By their application area: Residential or non-residential, general or industrial ventilation

As you might guess from the name, residential units are designed and used to ventilate apartments, single, or small multi-family houses. The airflow is usually limited up to 1,000 m3/h (cubic metres per hour).

These AHU tend to be much less complex than non-residential units, which are often highly tailored to cater to specific buildings and their requirements. Both residential and non-residential air handling units have different standards to meet, established by EU Ecodesign regulations.

By location: Outdoor or indoor

The most common situation for an AHU is outside or in auxiliary premises. Any outdoor units must be vigorously watertight and covered in a corrosion-resistant coating to prevent contamination or degradation. Smaller AHUs are often mounted above the ceiling.

What are the components of air handling units?

In general, an AHU’s purpose is to achieve improved indoor air quality. The first step in this is always to transfer outside air into the AHU for treatment. This process happens either directly, if the unit is placed outdoors, or via a duct system.

Inside the AHU, treatment begins to take place, with removing particulate matter from the air and thermally treating it to meet the specific application. This can either be heating the air or cooling the air.

The air is then distributed throughout the building. In the case of bidirectional units, the AHU simultaneously gathers extracted air from the duct system and transports it out of the building. All of this is done using a highly efficient energy recovery system to ensure that the machine is as energy efficient as possible.

The easiest way to understand exactly how an AHU functions is to break it down into its separate components and look at each one.

Air filters

The air filter in an AHU is designed to remove pollutants such as harmful fine dust, pollen, bacteria, and mould from the air supply and replace the contaminated air with clean, fresh air.

In addition to this, air filters also keep the air handling equipment clean to ensure efficient and hygienic operation.

Depending on the type of building, it may be useful to add additional filters to the AHU, including those specialised in removing odours, grease, or corrosion molecules.

These are some of the different filters available for AHUs :

- HEPA filters are often used to protect staff and sensitive equipment as these filters are efficient at removing particles and advanced models even remove airborne bacteria and viruses from the air

- Bag filters provide a medium to high-efficiency filtration

- Panel filters provide low-efficiency filtration

- Electrostatic filters use highly charged electrodes that ionize the air

- Carbon filters remove smells and gases

There are two main considerations around the energy efficiency of filters, the clean/initial pressure drop, and the pressure increase caused by filter dust load. Both of these have a significant influence on how efficient the AHU is.

An indicator for the energy efficiency of a filter is the Energy Efficiency Class of the Eurovent Certified Performance programme for air filters. Further essential information on air filters can also be found in the Eurovent Guidebook “Air filters for general ventilation” and the Eurovent 4/23 Recommendation on how to select ISO 16890 rated air filters for general ventilation purposes.

Energy recovery components

Climate has a large impact on how an AHU performs. During the majority of the year, the outdoor air temperature will deviate from the necessary supply air conditions. In this case, thermal treatment is required. To minimise the energy consumption of thermal air treatment, an Energy Recovery System (ERS, also commonly known as Heat Recovery System or HRS) should be applied.

If your country is a member of the European Union, the installation of an ERS has been mandatory since the Ecodesign Regulation (EU) No 1253/2014 was enforced.

An ERS works by transferring thermal energy from extracted air to the outdoor air. For example, in a typical European winter, this could mean that the outdoor air is warmed from -5°C to 15°C purely by the use of heat from the extracted air. In the summer, this process is reversed and the ERS is used to lower the cooler demand. This process is much more energy efficient, and places less demand on the system.

There are commonly three different types of ERS:

- Regenerative

- Most regenerators are rotary heat exchangers. A wheel rotates through both air streams and thereby transports the capacity. With rotary heat exchangers, there is always an air exchange between the outdoor and extract air.

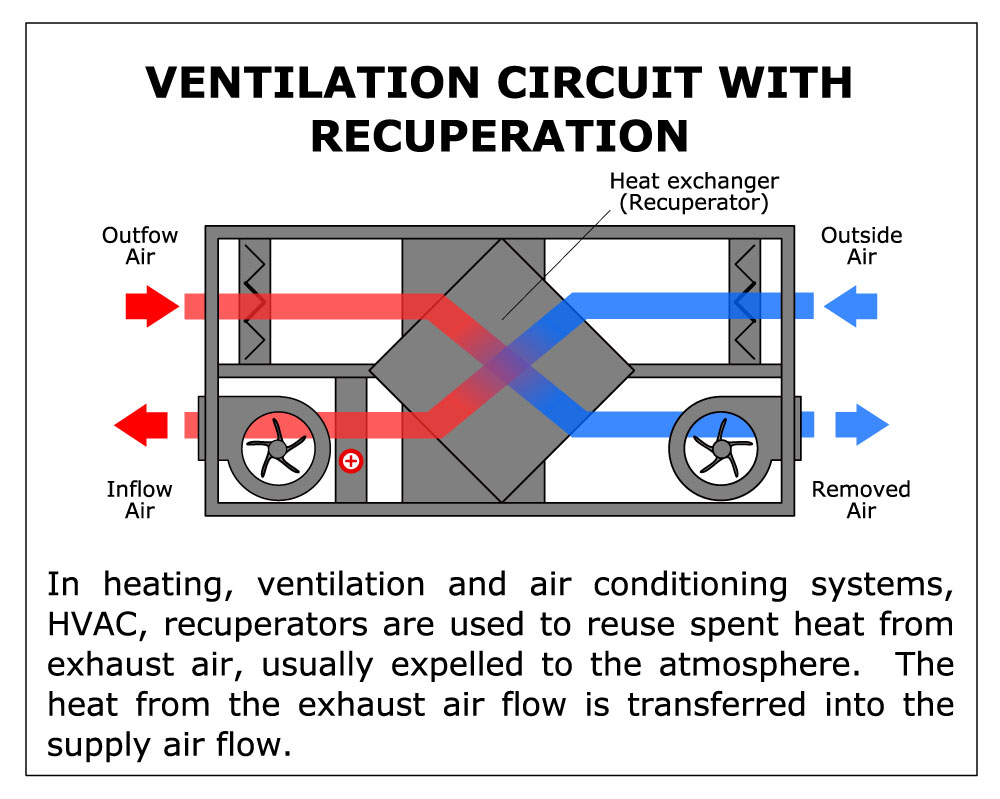

- Recuperative

- Recuperative systems guide the outdoor air inside and extract indoor air through very small ducts. This allows both airstreams to remain separate while they exchange thermal capacity with the help of specially designed surfaces. Normally, plate heat exchangers are used to facilitate the exchange of energy between inflowing and outflowing air.

- Run-around coils

- The third system keeps both air streams completely separated from each other so that cross contamination is impossible. They are called run-around coil systems. Here, the thermal capacity is transferred with a coil in the outdoor air to a water system and then brought to a coil in the extract air.

Heating and cooling components

While heat recovery systems provide some cooling and heating facilities, alone they are not enough to complete what is needed. In this instance, additional components for thermal treatment are required. Finned water to air compact heat exchangers are commonly used. These systems connect to the central heating and cooling systems of the building. It is also possible to incorporate a DX (direct expansion) coil in an AHU, which will act as the evaporator or condenser of a refrigerant circuit and cool or heat the processed air.

For heating, an electrical heater can also be used. Meanwhile, a cooling coil can be adapted to also have a dehumidifying effect in addition to its original utility. First it can be used in a dry manner. The water content in the supply air and outdoor air is similar, no condensation takes place. If used for dehumidification, then water collects as condensate and must be drained from the AHU with a drip tray and piping. To increase energy efficiency, the air and waterside pressure drops of heating and cooling coils should be as low as possible.

Fans

There are a variety of different fans available, including forward curved, backward curved, airfoil, and backward inclined. To determine the right fan, software is often used to assess the static pressure and air volume in the AHU. However, the main utility of each fan is the same – to move the air to different sections of the building.

The most commonly used fan is a direct-driven, free-running backward curved fan. Belt-driven fans are rarely used in modern AHUs due to their limited energy efficiency.

The fans are controlled by a motor to ensure that only the demanded airflow is generated. This speed control can be managed with frequency converters in case of AC motors, or with direct electronic controls in the case of PM/EC-fans.

The measure of the effectiveness of a fan is the fan efficiency. In Europe, fan efficiency is regulated by the European Commission Regulation (EU) No 327/2011, which prevents the use of inefficient fan/motor combinations in Europe.

Silencers

Depending on where the AHU is situated, there can be high requirements surrounding the noise level. In an AHU, noise is generated by components in the duct, or the unit. The main source of noise emissions is the fan. Therefore, the most advantageous place to install sound-reducing components is usually close to this source. In an AHU, silencers are usually placed directly up or downstream of the fan. However, if noise transfers occur from supply to extract air, or the other way around, other positions may be considered.

Silencers normally consist of splitters, which include an absorbing material. The sound of the impeller is reduced by the modification of the specific silencer. Considering energy aspects, the pressure drop of silencers should be as low as possible.

(De)Humidifier

Depending on the application of the AHU, humidity may be an important factor. Thus, it needs to be controlled and maintained in defined interval values.

There are two main ways to add humidity to air. Steam is most commonly used as it is a more accurate method. However, water in liquid form may also be used. Humidification with liquid water is an adiabatic evaporation process that collaterally cools the air. A heater is required upstream of the adiabatic humidifier to secure the supply air temperature.

Usually, applications requiring humidification also require dehumidification. The way to decrease the water content in the air is by using the cooling coil to cool the air in order to reach the saturated temperature. In those conditions, the air's water content will form a condensate.

Mixing section

The mixing chamber is where air changes from the extract unit to the supply unit side. The goal of mixing the recirculated air is to reach the perfect combination of air to be sent for conditioning. This can minimise thermal treatment requirements by combining the extract air to reach – as far as possible – the needed air temperature. This is a simple method of heat recovery. More complex methods, such as thermal wheel and cross plate heat exchangers also exist but consume more energy.

Other components

While the components listed are the most common, other components can also be useful depending on the requirement of the AHU.

Indirect adiabatic cooling can be placed upstream of the energy recovery system, in the extract air side. This component is only used under summer conditions. Where the extract air contains water, the water evaporates passing through the system and therefore the extract air is cooled down. This means that it streams with a reduced temperature into the energy recovery system.

As a result, the outdoor air will be cooled down to a much lower temperature after the heat recovery system than without an indirect adiabatic humidifier. Another relevant additional component can be the use of bypass systems to reduce the air resistance through other components of a unit when not in use.

An AHU for every type of building

It doesn’t matter what sort of building you are looking at for installing an AHU. With such a large, adaptable range of modules that can be added or subtracted as needed, there will be an AHU to suit your building's needs.

The key component to making the correct purchase is to do your research and decide what sort of AHU best suits your requirements.

This can be a confusing process, with lots of different information to take in. This is where Eurovent can help.

Eurovent certification

Eurovent has introduced a set of criteria for certifying and rating AHUs. This way, consumers can make an educated and suitable purchase of air handling equipment to cleanse the air in their indoor spaces.

Mechanical characteristics

The following mechanical characteristics are certified:

- Casing strength (CS)

- Casing air leakage (CAL)

- Filter bypass leakage (FBL)

- Thermal transmittance of the casing (TT)

- Thermal bridging factor (TBF)

- Acoustical insulation of casing

Performance characteristics

The following performance characteristics are certified:

- Airflow – available static pressure – power input

- Octave band in-duct sound power level

- Airborne sound power level

- Heating capacity*

- Cooling capacity*

- Heat recovery*

- Pressure loss on water side*

* If standard features of the product range

The Eurovent certification makes it easy to compare equipment objectively and choose the AHU that satisfies your requirements most easily.

That’s far from the only benefit of certification. It can also:

- Introduce an industry standard for measuring the performance of AHUs. When comparing products from different countries, the vital information may be displayed in different measurements making it difficult to evaluate. Using the same certification for all AHUs means parameters are simpler and easier to understand for consumers.

- Eurovent is an impartial, independent, and professional accredited body that provides an objective score based on its own findings.

- Certified products comply with recognised standards making them much safer to use.

- The consumer can rest easy in the knowledge that the certified products will work according to the specifications stated by the manufacturer thanks to independent testing.

Related technical insights

Regulations

Regulations

Air Handling Units

Regulations

Regulations